The world’s love affair with jewelry shows no signs of slowing down. Consumer demand for unique and beautiful pieces continues to rise. However, for jewelry businesses, this surge in popularity presents a challenge: how to scale up production while maintaining the exquisite quality and craftsmanship that customers expect.

Traditionally, jewelry making has often relied on manual processes, which can be time-consuming and limit output. This is where automated and semi-automated stamping solutions come into play. These innovative technologies offer a compelling answer for businesses seeking to increase production efficiency without sacrificing the quality of their pieces.

What is Stamping and How Does it Apply to Jewelry Production?

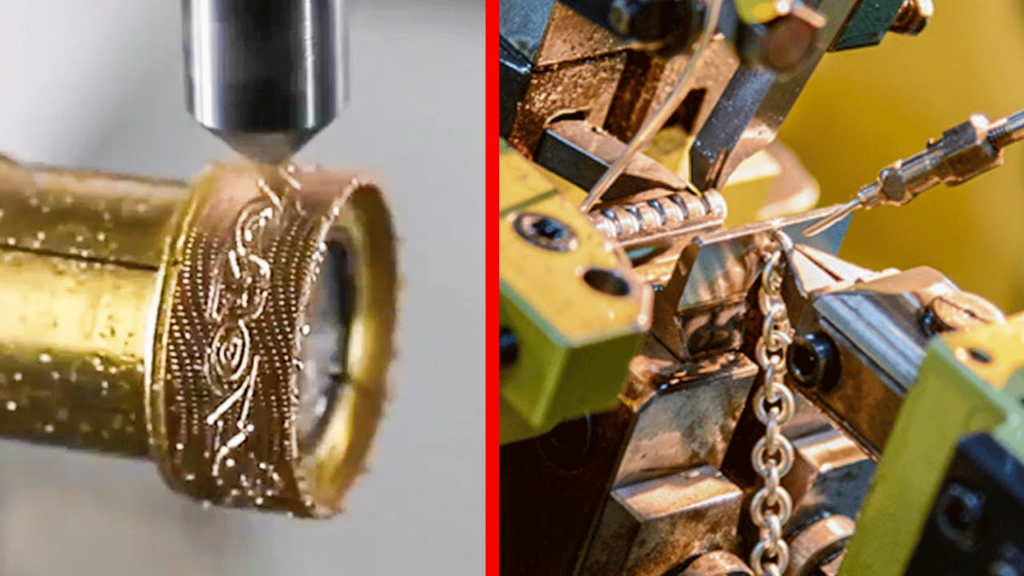

Metal stamping is a technique that uses a metal stamp (a die with a design) and a hammer (or press) to permanently imprint a design, letters, numbers, or symbols onto a piece of sheet metal. In the world of jewelry making, stamping is a versatile tool used to create a wide variety of effects:

- Adding logos, brand names, or personalized messages onto jewelry pieces like pendants, charms, and bracelets.

- Creating decorative patterns and textures on bangles, rings, and other jewelry components.

- Shaping and forming sheet metal into specific shapes for jewelry making.

There are three main types of stamping techniques used in jewelry production:

Manual stamping: This is the traditional method, where a jeweler uses a hammer and individual metal stamps to create designs. It requires skill and precision but offers the most flexibility for intricate work.

Automatic stamping: This technique utilizes high-speed, computer-controlled machines that can stamp intricate designs with incredible speed and consistency.

Semi-automatic stamping: This method combines elements of both manual and automatic stamping. The machine feeds the metal and positions the stamp, while the operator controls the stamping action, allowing for more control over intricate designs compared to fully automated systems.

The benefits of stamping for jewelry production are numerous:

Speed and efficiency: Stamping allows for mass production of identical pieces, significantly increasing output compared to manual methods.

Consistency: Stamped designs are always crisp and precise, ensuring a uniform look across your jewelry line.

Versatility: A wide variety of stamps and techniques allow for the creation of simple or highly detailed designs.

By incorporating stamping into their production process, jewelry makers can achieve the perfect balance of speed, consistency, and beautiful design.

Exploring Automated Stamping Solutions

Automated stamping machines are marvels of modern engineering. These machines are essentially robots equipped with a stamping head and a feeding mechanism for metal blanks. The operator programs the desired design and production run, and the machine takes care of the rest. The stamping head precisely positions itself and delivers a powerful, controlled force to create the design on the metal.

The advantages of automation in jewelry production are undeniable:

Increased production speed: Automated machines can stamp hundreds or even thousands of pieces per hour, significantly boosting output compared to manual or semi-automated methods.

Reduced labor costs: With minimal operator intervention required, automation can help reduce labor costs associated with high-volume production.

Improved consistency: Automated machines ensure every stamped piece is identical, eliminating human error and guaranteeing a uniform product.

However, it’s important to consider some potential drawbacks of full automation:

High initial investment: Automated stamping machines can be expensive, making them a significant upfront cost for smaller businesses.

Limited flexibility for complex designs: While automation excels at replicating simple designs with high precision, intricate or artistic details might be difficult or impossible to achieve with fully automated systems.

For businesses with high-volume production runs and a focus on consistent, simple designs, automated stamping solutions offer a compelling path to increased efficiency and profitability.

Unveiling the Advantages of Semi-Automated Stamping

Semi-automated stamping machines bridge the gap between manual and fully automated stamping. These machines offer a blend of human control and mechanical efficiency. The machine typically handles the repetitive tasks of feeding the metal and positioning the stamp, while the operator controls the activation of the stamping mechanism. This allows for a more nuanced approach compared to fully automated systems.

Here’s where semi-automated stamping truly shines:

Increased efficiency: Compared to manual stamping, semi-automated machines significantly boost production speed while still requiring less investment than fully automated solutions.

Operator control for intricate designs: The operator’s ability to control the stamping action allows for greater precision and flexibility. This is ideal for creating complex designs or incorporating unique details into each piece.

Cost-effectiveness: Semi-automated machines offer a more affordable entry point into mechanized stamping compared to fully automated systems. This makes them a viable option for businesses looking to scale up production without breaking the bank.

By combining the speed and precision of automation with the control and artistry of a skilled craftsperson, semi-automated stamping provides a compelling solution for businesses seeking to produce high-quality jewelry with increased efficiency and design flexibility.

Choosing the Right Stamping Solution for Your Needs

Selecting the ideal stamping solution for your jewelry business hinges on several key factors:

Production volume: Consider your current and projected production needs. If you’re dealing with high-volume orders and prioritize consistent, simple designs, then automation might be the way to go.

Budget: Automated machines come with a hefty price tag, while semi-automated options offer a more budget-friendly entry point. Factor in your initial investment capabilities and long-term return on investment.

Design complexity: The level of detail and artistry desired in your jewelry plays a crucial role. For intricate or highly customized designs, the operator control offered by semi-automated machines becomes invaluable.

Here’s a quick breakdown to help you decide:

Ideal scenarios for automation:

- High-volume production runs

- Jewelry with simple, repeatable designs (logos, letterings)

- Businesses prioritizing speed and consistency

Ideal scenarios for semi-automation:

- Moderate production volumes

- Jewelry with intricate designs or unique details

- Businesses seeking a balance between efficiency and design flexibility

- Businesses with budget constraints

Ultimately, the best choice depends on your specific needs and priorities. Consider consulting with a stamping equipment supplier to discuss your requirements and find the solution that best fits your business model.

Additional Considerations for High-Volume Jewelry Production

While selecting the right stamping solution is crucial, there are other important aspects to consider when scaling up jewelry production:

High-quality metal blanks: The foundation for beautiful stamped jewelry starts with high-quality metal blanks. Choose blanks with a consistent thickness, clean surface, and appropriate temper (hardness) for your chosen stamping technique.

Integration with other processes: Stamping is just one step in the jewelry-making journey. Ensure smooth integration of stamping with other processes like finishing (removing surface imperfections) and polishing (bringing out the metal’s shine).

Quality control measures: Maintaining consistent quality is paramount in high-volume production. Implement a quality control system to inspect stamped pieces for defects like cracks, uneven stamping, or misaligned designs. This ensures your finished jewelry meets your high standards.

By paying close attention to these details, you can streamline your production process and ensure a consistent flow of beautiful, high-quality stamped jewelry.

The Future of Stamped Jewelry: Scaling Up with Innovation and Quality

The world of jewelry making is constantly evolving, and automated and semi-automated stamping solutions are at the forefront of this progress. These innovative technologies offer a powerful toolkit for businesses seeking to scale up production while maintaining the exquisite quality their customers expect.

Looking ahead, the future of stamping technology promises even greater possibilities. By embracing these innovative solutions, jewelry businesses can ensure they are well-equipped to meet the growing demand for beautiful, high-quality pieces, propelling their brand to new heights of success.

Royi Sal Jewelry, a leading manufacturer of silver and gold jewelry based in Thailand, has been leveraging the power of stamping technology for over 20 years. They offer a wide range of services, including OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) to help businesses bring their jewelry visions to life. Whether you’re a seasoned jeweler or just starting, exploring the possibilities of automated and semi-automated stamping with a company, Royi Sal Jewelry can empower you to take your creations to the next level.

Share this post