Jewelry manufacturing creates jewelry from raw materials, such as precious metals, gemstones, and pearls. It involves various techniques, including casting, forging, fabrication, wireworking, beading, enameling, stone setting, polishing, and plating.

What are the different types of jewelry manufacturing techniques?

Casting

Casting is one of the most famous jewelry manufacturing techniques. It involves melting metal and pouring it into a mold. The mold is then cooled, and the metal is removed. Casting can be used to create jewelry pieces with various shapes and designs.

How does casting work?

There are two main types of casting: sand casting and investment casting.

- Sand casting is a traditional casting technique that uses a sand mold. The sand mold is created by pressing a pattern into the sand. The pattern is then removed and the molten metal is poured into the mold cavity.

- Investment casting is a more precise casting technique that uses a wax mold. The wax mold is created by injecting molten wax into a mold cavity. The wax mold is then coated with a plaster investment material. The investment material is then heated to melt the wax and harden the plaster. The molten metal is then poured into the investment mold cavity.

Once the molten metal has cooled and solidified, the mold is broken away to reveal the finished jewelry piece.

Examples of cast jewelry

Cast jewelry is prevalent and can be found in all price ranges. Here are a few examples of cast jewelry:

- Rings: Rings are one of the most popular types of cast jewelry. Cast rings can be made from a variety of metals, including gold, silver, platinum, and palladium. Cast rings can also be set with gemstones.

- Necklaces: Necklaces are another popular type of cast jewelry. Cast necklaces can be made from a variety of metals and can be set with gemstones or pearls.

- Earrings: Earrings are a popular type of cast jewelry for both men and women. Cast earrings can be made from a variety of metals and can be set with gemstones or pearls.

- Bracelets: Bracelets are a popular type of cast jewelry for both men and women. Cast bracelets can be made from a variety of metals and can be set with gemstones or pearls.

- Pendants: Pendants are a popular type of cast jewelry for necklaces. Pendants can be made from various metals and can be set with gemstones or pearls.

Stamping

Stamping is a metalworking process in which a design is impressed into a piece of metal using a die. The die is a hardened steel tool that contains the desired format in reverse. The metal is placed between the die and a punch, and then the punch is driven into the metal, forcing the metal into the die and creating the design.

Stamping is used in jewelry manufacturing to create various designs on jewelry pieces, including letters, numbers, symbols, and decorative patterns. Stamping can also create hollow jewelry pieces, such as beads and tubes.

There are two main types of stamping used in jewelry manufacturing: hand stamping and machine stamping.

Hand stamping is done using a hand-held stamp and hammer. Hand stamping is a relatively slow and time-consuming process, but it allows for a great deal of creativity and precision. Hand-stamped jewelry is often prized for its unique and personal character.

Machine stamping is done using a stamping machine. Machine stamping is much faster and more efficient than hand stamping, but it is not as flexible. Machine-stamped jewelry is often mass-produced and is typically less expensive than hand-stamped jewelry.

Stamping is a versatile and efficient jewelry manufacturing technique that can create various jewelry pieces, from simple to complex.

Here are some examples of how stamping is used in jewelry manufacturing:

- Stamping initials or names onto jewelry pieces

- Stamping decorative patterns onto jewelry pieces

- Stamping designs onto jewelry tags

- Stamping serial numbers onto jewelry pieces

- Stamping hallmarks onto jewelry pieces

Hallmarks are symbols or letters stamped onto jewelry to indicate its purity, origin, and maker. Hallmarks are essential for ensuring the quality and authenticity of jewelry.

Stamping is an essential part of jewelry manufacturing to create various jewelry pieces.

Wireworking

Wireworking is a jewelry-making technique that involves bending, shaping, and weaving wire to create jewelry. Wireworking is a versatile technique used to create various jewelry pieces, from simple to complex.

Wireworking is used in jewelry manufacturing to create a variety of pieces, including:

- Necklaces

- Bracelets

- Earrings

- Rings

- Pendants

- Charms

- Chains

- Findings (such as earwires, jump rings, and clasps)

Wireworking can be used to create jewelry pieces in a variety of styles, including:

- Wire wrapping

- Chainmaille

- Beading

- Filigree

- Wire sculpture

Wire wrapping is a wireworking technique that involves wrapping wire around beads, stones, and other objects to create jewelry pieces. Wire wrapping is a popular technique for making handmade jewelry and can be used to create various designs, from simple to complex.

Chainmail is a wireworking technique that involves weaving wire rings together to create jewelry pieces. Chainmaille is an ancient technique used for centuries to make jewelry and armor. Chainmaille jewelry is often characterized by its intricate and geometric designs.

Beading is a wireworking technique that involves stringing beads together to create jewelry pieces. Beading is a popular technique for creating handmade jewelry and can be used to create various designs, from simple to complex.

Filigree is a wireworking technique that involves bending and shaping wire to create delicate, intricate designs. Filigree jewelry is often characterized by its delicate and airy appearance.

Wire sculpture is a wireworking technique that involves bending and shaping wire to create three-dimensional objects. Wire sculpture jewelry is often characterized by its unique and artistic designs.

Wireworking is a versatile and creative jewelry-making technique that can create various jewelry pieces.

Here are some examples of how wire working is used in jewelry manufacturing:

- Wire wrapping a bead to create a pendant

- Weaving chain maille rings to create a bracelet

- Stringing beads on wire to create a necklace

- Bending and shaping wire to create a filigree pendant

- Sculpting wire to create a three-dimensional ring

Wireworking is an integral part of jewelry manufacturing and is used to create various jewelry pieces.

Beading

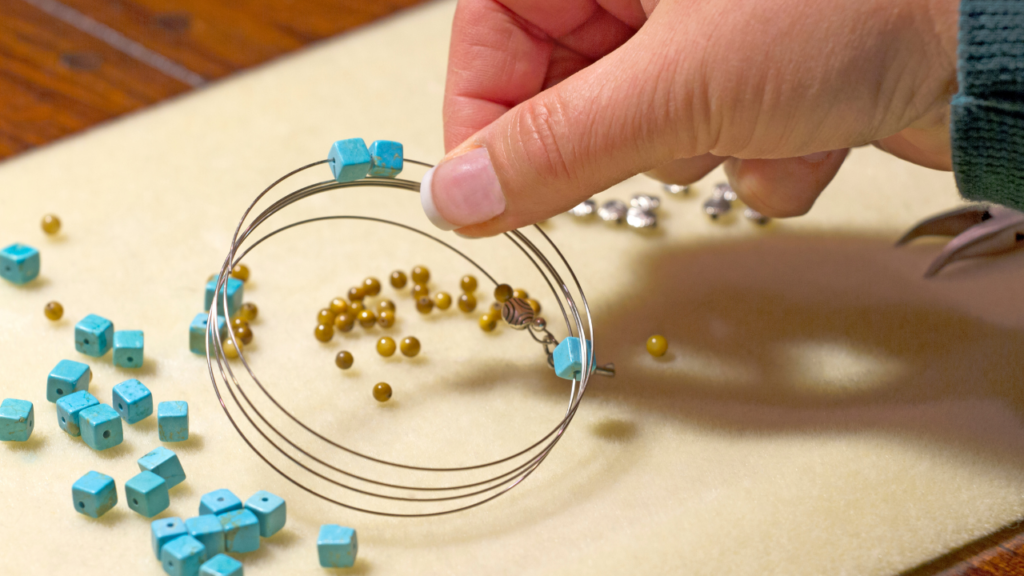

Beading is a jewelry-making technique that involves stringing beads together to create jewelry pieces. Beading is a popular technique for creating handmade jewelry and can be used to create a wide variety of designs, from simple to complex.

Beads come in a variety of materials, shapes, and sizes, which makes beading a versatile technique for creating jewelry. Some popular beading materials include:

- Glass beads

- Crystal beads

- Pearl beads

- Seed beads

- Metal beads

- Wooden beads

- Stone beads

- Ceramic beads

- Polymer clay beads

Beads can be strung together using a variety of different techniques, including:

Stringing beads on a single strand: This is the most straightforward beading technique and involves stringing beads onto a single strand of wire or thread.

Stringing beads on multiple strands: This technique involves stringing beads onto two or more strands of wire or thread to create a more complex and durable piece of jewelry.

Bead weaving: Bead weaving is a more advanced beading technique that involves weaving beads together to create intricate designs.

Beading is used in jewelry manufacturing to create a variety of pieces, including:

- Necklaces

- Bracelets

- Earrings

- Rings

- Pendants

- Charms

- Anklets

- Hair ornaments

- Clothing embellishments

Beading can be used to create jewelry pieces in a variety of styles, including:

- Traditional: Traditional beading styles often incorporate geometric patterns and motifs.

- Contemporary: Contemporary beading styles often incorporate unique and innovative designs.

- Ethnic: Ethnic beading styles often incorporate traditional designs and materials from different cultures.

Beading is a versatile and creative jewelry-making technique that can create various jewelry pieces.

Here are some examples of how beading is used in jewelry manufacturing:

- Stringing glass beads on a single strand to create a simple necklace

- Stringing crystal beads on multiple strands to create a more complex bracelet

- Weaving seed beads together to create an intricate bead woven pendant

- Using metal beads to create a durable and stylish ring

- Combining wooden beads with other materials to create a unique and eye-catching piece of jewelry

- Using stone beads to create a piece of jewelry with natural beauty

- Using ceramic beads to create a piece of jewelry with a handcrafted feel

- Using polymer clay beads to create a piece of jewelry with endless possibilities

- Beading is an integral part of the jewelry manufacturing process and is used to create various jewelry pieces.

Enameling

Enameling is a jewelry making technique that involves applying a layer of glass to a metal surface. The enamel is then fired in a kiln to melt the glass and fuse it to the metal. Enameling can be used to create a variety of decorative effects on jewelry pieces, including:

- Solid colors

- Translucent colors

- Opaque colors

- Multicolored designs

- Textured designs

- Cloisonné designs

- Champlevé designs

- Plique-à-jour designs

Enameling is used in jewelry manufacturing to create a variety of pieces, including:

- Necklaces

- Bracelets

- Earrings

- Rings

- Pendants

- Charms

- Pins

- Cufflinks

- Tie bars

- Money clips

Enameling can be used to create jewelry pieces in a variety of styles, including:

- Traditional: Traditional enameling styles often incorporate geometric patterns and motifs.

- Contemporary: Contemporary enameling styles often incorporate unique and innovative designs.

- Ethnic: Ethnic enameling styles often incorporate traditional designs and materials from different cultures.

Cloisonné is a type of enamel in which the enamel is applied to areas of the metal enclosed by thin metal wires. The wires create cells, or cloisons, that hold the enamel in place.

Champlevé is a type of enamel in which the enamel is applied to recessed metal areas. The open areas are created by chiseling or carving into the metal.

Plique-à-jour is a type of enamel in which the enamel is applied to a perforated metal surface. The perforations allow the light to shine through the enamel, creating a translucent and ethereal effect.

Enameling is a versatile and creative jewelry making technique that can be used to create various jewelry pieces.

Here are some examples of how enameling is used in jewelry manufacturing:

- Enameling a copper pendant with a solid blue color

- Enameling a silver bracelet with a translucent green color

- Enameling a gold ring with an opaque white color

- Enameling a silver necklace with a multicolored floral design

- Enameling a copper cufflink with a textured design

- Creating a cloisonné enamel pin with a geometric design

- Creating a champlevé enamel pendant with a floral design

- Creating a plique-à-jour enamel earring with a butterfly design

Enameling is an essential part of jewelry manufacturing to create various jewelry pieces.

Conclusion

In conclusion, jewelry manufacturing is a dynamic and innovative industry constantly evolving. The most popular jewelry manufacturing techniques are casting, stamping, wireworking, beading, and enameling. Each method has unique benefits and can be used to create various jewelry pieces, from simple to complex.

The future of jewelry manufacturing will likely see a continued trend toward automation and new technologies, such as 3D printing, laser cutting, waterjet cutting, and electroforming. These new technologies are allowing jewelry manufacturers to create jewelry pieces that are more complex, intricate, and durable than ever before.

In addition to new technologies, other trends that are shaping the future of jewelry manufacturing include increased use of sustainable materials, personalization, and mass customization. Jewelry manufacturers are constantly innovating to create new and innovative jewelry pieces that meet the needs and desires of consumers.

Overall, the future of jewelry manufacturing is bright and exciting.

Share this post